If you've inspected your push rod and found broken or cracked welds, bends, missing roll pins or worn bushings, removal of the push rod is likely necessary. This guide will show you how to remove the push rod(s) from your pallet jack.

Removal

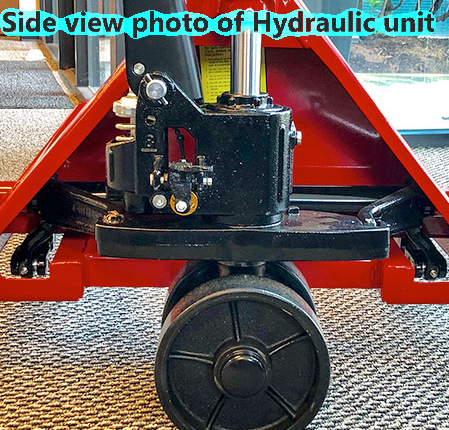

Turn the jack over so the undercarriage section is exposed. Remove the load roller brackets (see Load Roller Brackets).

Loosen the nut on the push rod and then the push rod can be threaded off the eye bolt.

The eye bolt can be removed with the push rod by using a hammer and pin punch to drive the roll pin out of the pin that fastens the eye bolt to the lifting link.

Remove the pin and the push rod. The eye bolt can then be removed from the jack.

Note:

The nut on the eye bolt is primarily a marker for proper adjustment. It also keeps the eye bolt or push rod from spinning out of adjustment when working on the load roller brackets or lifting link.

Email or call (800)331-0839 today for your replacement parts!