Tips for Pallet Jack Safety

They might not be as large and fast as forklifts, but accidents still happen!

The Pallet Jack Pros at Generic Parts compiled some tips (and the list is by no means complete) to keep everyone in the warehouse safe, and to avoid property damage:

Inspect your pallet jack before every use

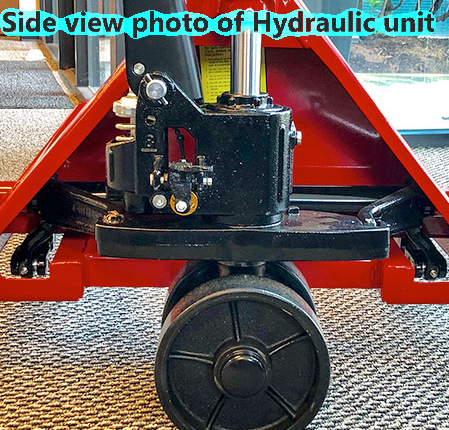

Always use a jack that is in good shape! Make sure to test the jack thoroughly - rotating the handles, raising and lowering the jack, rolling the wheels, and so on. Replace any parts not working properly immediately to avoid major equipment damage.Wheels and rollers need to be replaced most often since they get the most wear. We have wheels for all the major brands and ship same-day. Our convenient pre-packaged wheel kits contain all parts needed for replacement.

If you not sure how to replace the load rollers or steer wheels, our step-by-step videos will help. You will find other convenient videos on our YouTube channel to help you replace the handle, rebuild the hydraulic unit, and more.

Give sufficient Clearance

Make sure your pallet jack won't unexpectedly catch on anything. Lift the load to give it 1 inch of clearance off the ground. Most of the time that is enough, but check the route in advance to make sure.

Don't let hands or feet get under it

Always be conscious of where you are standing or placing your hands around its forks as you lower the jack. Most of the time raising or lowering the jack is no problem, but don't risk that it will fail and come crashing down with disastrous consequences.

Also be aware of the places where the "pinch" motion could catch your hands or feet. Often hurried work and inattention can lead to avoidable accidents.

Ask for help if you need it

When pushing a jack with a big load that you can't fully see over or around, it's important to not try to move it anyway. Instead, enlist the help of a coworker to ensure you don't run into anything or anyone.

Do not stack materials higher that eye level!

Pull, don't push

Pull the pallet jack whenever possible. Pushing the equipment makes it less maneuverable and you risk running into something, or someone, when going around a corner.

Know your Load

To prevent an unstable load, use a container for smaller items and secure larger items by bundling them up. Make sure the load is evenly distributed. A top-heavy load can tip over. Always load the heaviest items first. Center the forks evenly under the load to maintain good balance and stability and make sure the forks are positioned completely under the pallet. Never overload.

OSHA recommends limiting the weight of loads so the necessary pushing force is less than 50 pounds.

Use Personal Protective Equipment (PPE)

It’s important to have all the vital tools and equipment to make each lifting or handling job both easy and safe. Here are the necessities:

Leather Gloves: Use leather gloves when working with large, heavy materials that have sharp or rough edges.

Back Belts: A back belt is helpful in supporting your lower back while using hand trucks, carts, and pallet jacks. Make sure you have the proper fit and that it is being worn on your lower back.

Protective Footwear: Transporting items in certain areas can put you at risk for foot injuries due to falling, rolling objects or pointed materials that can pierce the sole. You may also need special designs of footwear like non-skid soles and steel-toed boots when there are slip or trip hazards in your worksite.

Additionally

we recommend the pallet truck toe guard, to reduce the risk of the pallet jack rolling over your foot.

Use a pallet jack stop to prevent the jack from rolling out of control especially on an incline.

Remember, Generic Parts Service has quality replacement parts for your pallet jack in stock, and we ship same day if you order before 6 P.M. (EST).

We also carry replacement parts for electric lift trucks and forklifts.

Is pallet jack beyond repair, or you need additional ones? Take a look at our line of quality jacks here.

This information is intended for general information purposes only. This is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion.