A common question we run across in pallet jack maintenance is "When do I replace the wheels on our equipment"? Of course you may need it when if it's dropped off a dock but your equipment will last longer if regular routine maintenance is performed.

To help out our customers we've created this reference guide for manual pallet jack steer wheels and load wheels. Below is a brief overview of the process, however we recommend printing it out for the full details and storing with your reference material. We advise performing the below inspection points every 6 months.

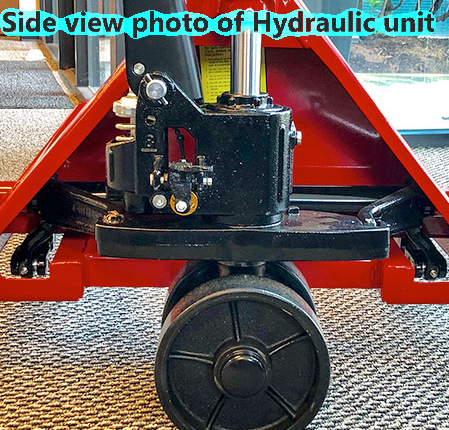

Pallet Jack Wheel Inspection

1. Test raise & lower function. If unit will not lift, bleed hydraulic unit by pumping handle 10 times with control lever in release position.2. Once you have verified that the pallet jack will raise and lower, inspect both steer wheels and load wheels. Replace wheels if worn down .25" from new, debris is embedded in material or inhibiting the wheel from turning freely.

Note: Always replace both load wheels or steer wheels even if only one wheel meets the criteria for replacement.

3. Inspect the entry rollers. If they do not turn freely or are visibly damaged, replace.

Pre-Packaged Wheel Kits

Once you know you need to replace a set of Load Wheels, Steer Wheels (or both), a Pre-Packaged Wheel Kit is the best option on the market. We were the first in the industry to create Pre-Packaged Wheel Kits. They are in stock and ready to ship same day for most manual and electric pallet jack models. Our goal is to make routine maintenance as easy as possible and we are excited to see how popular they have become among technicians.Pre-Packaged Load Wheel kits for electric and manual lifts come ready to install. You'll receive a pair of load wheels assembled with bearings plus the axles and fasteners. Have you ever encountered rusted axles that had to be cut off? Maybe you are cursed with roll pins or snap rings that flew away. Complete every job the first time by showing up with all the components you need.

Pre-Packaged Complete Wheel Kits for manual pallet jacks come with all components you receive in a Load Wheel Kit, plus both steer wheels, bearings, steer wheel axle and fasteners. It's a great idea to have a couple extras in stock to stay ahead of emergencies, (as in the jack fell off the dock and now can't unload that shipment).

We do understand customers who want to be frugal by re-using axles if possible. To that end, in many cases the kits are less expensive than ordering even just the wheels separately. After 30+ years of putting our customers first we feel bad when an additional order has to be placed for a second load wheel or axles (or those air-born roll pins!). No one wants to pay shipping twice and wait days for delivery.

We do understand customers who want to be frugal by re-using axles if possible. To that end, in many cases the kits are less expensive than ordering even just the wheels separately. After 30+ years of putting our customers first we feel bad when an additional order has to be placed for a second load wheel or axles (or those air-born roll pins!). No one wants to pay shipping twice and wait days for delivery.Check out the Extensive model lists we carry Wheel Kits for:

Electric lift trucks

What to do if you find the axles are rusted or frozen in place and you need some guidance? We've got you covered there as well. We have a collection of YouTube videos to guide you. Check out the links below!

How-to videos:

- Replace the load wheels on your pallet jack

- Replace the steer wheels on your pallet jack

- How-to Install the handle on your new pallet jack

- How to remove a corroded load wheel axle

Save ...

...Time with Same-Day Shipping

...Time with Same-Day Shipping... Money with Free Shipping on Orders over $450*

*Commercial ground shipping within Continental US Only. Some items excluded

Ready to learn more or place an order?

Call our highly knowledgeable customer service (800)331-0839

or email csinfo@genericparts.com