Thursday, December 16, 2021

Wednesday, November 17, 2021

How to Bleed the Air out of the Hydraulic Unit

Now that you have added oil, you may need to bleed the air out of the hydraulic unit.

Have a suggestion for a future blog post?

Need help ordering parts from www.genericparts.com?

Give our friendly Customer Service team a call at 800-331-0839 or e-mail us at csinfo@genericparts.com

Monday, October 25, 2021

How to flip a pallet jack over

How to safely turn over a pallet jack

You need to do some work on your pallet jack and you need to flip it over.

Have a suggestion for a future blog post? Need help ordering parts from www.genericparts.com?

Give our friendly Customer Service team a call at 800-331-0839 or e-mail us at csinfo@genericparts.com

Friday, September 24, 2021

How much hydraulic oil?

Have you ever wondered how much hydraulic oil to add to your pallet jack?

Watch this video to find out more!

Friday, July 30, 2021

Most worn parts on a forklift

Forklift Parts You Need To Keep An Eye On

|

Forklifts require regular maintenance and daily checks. You should make sure the most important forklift parts are checked and double-checked! Some parts contribute more than others when it comes to safe use. Keep the parts listed below always properly maintained.

Unexpected downtime due to breakdowns can have a negative impact on operations. We recommend to have common forklift parts on hand for maintenance and repairs.TiresIf your forklift tires are bald, cracked or worn you need to replace them - before an accident happens! Without the correct tires, with sufficient tread, the driver risks losing control of the forklift, especially on smooth floors.

Warning Indicators

The lights, signals, horn and more are taken to be a single part which works for accident prevention. Included in the warning indicators is the display showing pressure and temperature of the transmission and engine. Fixing any faults with warning indicators can prevent further costs down the line. Regular checks and maintenance are proven to be the best method to stay ahead of problems.

Brakes

A forklift's brakes could be considered the most important part to regularly check and maintain. They are constantly working to decelerate and stop your forklift after every movement, often while the unit is carrying large amounts of cargo. Whether your unit has brake pads, drum brakes or other braking system such as oil-cooled, your brakes will need to be replaced regularly. It is imperative to check and replace worn-out brakes at the first sign of wear to ensure the forklift can be stopped safely and in a timely manner. Failure to maintain brakes properly will more than likely result in injury, even fatality, and product or capital equipment damage.

Mast Chains

Mast chains are used to extend a forklift's mast and carriage. With every movement they are put under incredible strain. As they're responsible for the lifting of heavy loads and managing the weight at extended heights, mast chains need to be checked on a regular basis and replaced at the first sign of wear or damage. Failure to properly maintain and replace damaged mast chains can lead to severe injuries, fatalities, and product damage.Filters

Regularly replacing filters as per manufacturer's routine maintenance guidelines is imperative to prolonging the operating life of a forklift. Dirty or clogged filters can be a sign of an operating area with poor air quality or cleanliness that needs improving for better health and safety.Friday, June 25, 2021

Generic Parts Specializes in Replacement Parts for Electric Lift Trucks, Electric Walkie Jacks, and Manual Pallet Jacks.

Generally, Electric Walkies get a lot of use and abuse. Our GW Wheels and Wheel Kits, Chargers, and large inventories of hard parts make us a great source for high quality and lower costs.

Wheels need to be replaced. Check out our selection of Wheel kits and Tires:

Electric Walkies normally have four 6 volt batteries onboard (24 volts) as well as their own battery charger. We see fair demand for our chargers. In terms of how the Walkies are used to load and unload trailers or move pallets in stores, delivery trucks with lift gates often carry their own walkie jacks plugged in overnight to recharge.

Have a suggestion for a future blog post? Need help ordering parts from www.genericparts.com?

Give our friendly Customer Service team a call at 800-331-0839 or e-mail us at csinfo@genericparts.com

Wednesday, May 12, 2021

Steer Wheels - which ones are best for your pallet jack?

There is a host of different materials for steer wheels available.

Polyurethane and Ultra-Polyurethane treads are the most common wheel

treads you'll encounter on a pallet jack.

What's best for your pallet jack depends on where and how you use it.

Poly Tread on Nylon Hub

These have a chemical bond that secures the poly tread to a steel core (or hub). This option is ideal for display floors, carpeting, and warehouses. They mark floors the least while rolling easily and quietly. Under really heavy loads (2,500lb +), if left to sit for more than 8 hours, there is a possibility of the wheels flat-spotting.

Ultra-Poly Tread on Aluminum hub

Longer lasting and they roll more easily than regular poly, also a chemical bond on a steel core. Ultra-poly is very hard and won't shatter like nylon if too cold (i.e. in and out of a freezer). They are also non-marking with the possibility of flat-spotting, as mentioned above.

Solid Nylon Wheel

This is a harder material that is best for cold storage applications. It is also the material of choice for use in environments that may cause rust or corrosion like poultry processing, and working with seafood. It can also be the best choice for refrigerated transport trucks that have grated floors. Lastly, they can be a good choice if the pallet truck is taken outside on the rough pavement. However these are more likely than poly to mark floors, so be mindful when using inside a showroom or a hotel lobby, for example.

Solid Steel Wheel

When all else fails you may need solid steel wheels. These are best for use on factory floors where there may be metal shavings or hard debris on the floor, and where noise is not an issue. What they lack in their ability for use in a sneak attack (they’re pretty loud) they make up for in sheer durability. These are also a good choice if you need to work outside on rough asphalt. But they can damage nice floors, so avoid use on floors you want to remain "pretty".

One Wheel or Two?

Now that you've got an idea of which type of wheel is best

for your specific uses you are faced with another sometimes tough decision. One

wheel or two?

First, most pallet jacks have two steer wheels. They are located on the main

body of the jack, attached to the hydraulic unit, and therefore the

handle.

Unless a pallet jack is brand new, we always recommend

replacing both steer wheels at the same time. There is a legitimate benefit:

Steer wheels wear down and get shorter the longer you have used them. Steer

wheels (like pallet jack load wheels, or the tires on your car) do not act

independently but are a portion of a larger machine. Even a small difference in diameter causes stress on the mating (aka connected) parts which

then causes issues down the line.

You find all variation wheels for most pallet jack brands here.

Because we so strongly advocate changing both at the same time we created wheel kits to get you everything you need, even the load wheels, and they are priced so that the hardware comes for free.

Here is an example:

Complete wheel kit for Crown PTH 50

Additional resources:

How do I find out the make and model of my pallet jack?

Video: How to turn a pallet over

Step-by-step video on how to replace your steer wheels

Step-by-step video on how to replace your load wheels

And more videos

Have a suggestion for a future blog post? Need help ordering parts from www.genericparts.com?

Give our friendly Customer Service team a call at 800-331-0839 or e-mail us at csinfo@genericparts.com

Friday, April 2, 2021

General Maintenance on Your Pallet Jack

Keeping your pallet jack in good working condition limits its downtime, and saves you money in the long run.

Here are some helpful hints when repairing and performing maintenance on your pallet jacks

- Never hammer directly on an axle; always use a pin punch.

- Always replace old roll pins. It is very important to use the correct roll pin to prevent damage to the mating (=connecting) parts.

- Replace accessible bushings whenever the jack is disassembled. Our custom-designed bushing extractor makes it quick and easy to remove all bushings.

Load Rollers

Need to replace your load wheels - See current pricing and availability here.

Handle

If bushings are not replaced regularly, the handle bracket holes can become worn. Damaged holes cause pin failure and may require complete replacement. Also, inspect the handle pin and roller for flat areas and wear. If any of the above parts are worn more than 1/16", replace them.

Hydraulic Unit Service Hints

• Tampering and abuse are two of the most common problems. In most cases, minor repairs become major when inexperienced people attempt to rebuild a hydraulic unit. If you come across a unit that looks like it has been tampered with or modified, inspect the unit carefully to be sure it can be rebuilt or call Generic Parts Service for technical assistance (1-800-331-0839).• The pump piston and ram are polished to a fine finish for maximum seal life and minimum oil leakage. If you see these surfaces nicked or pitted, this will cause the unit to fail in a short time. Replace any rusty or damaged parts that will cause premature wear on their mating parts or the body of the hydraulic unit.

• Use UNI-HO hydraulic oil. Do not use automotive oil or hydraulic brake fluid.

You find quality replacement parts for most brands of pallet jacks on our website www.GenericParts.com. We ship same day! (if ordered by 6:00 p.m. EST)

Have a suggestion for a future blog post?

Need help ordering parts from www.genericparts.com?

Give our friendly Customer Service team a call at 800-331-0839 or email us at csinfo@genericparts.com

Monday, March 1, 2021

Crown Pallet Jacks

Crown Pallet jacks are still some of the most popular we hear about.

Here are some helpful hints when repairing and performing maintenance on your Crown pallet jacks

- Never hammer directly on an axle; always use a pin punch.

- Always replace old roll pins. The PTH 50 has blind roll pin holes in the pivot axle and in the shoulder pins. It is very important to use the correct roll pin in these locations to prevent damage to the mating parts.

- Replace accessible bushings whenever the jack is disassembled. Our custom designed bushing extractor makes it quick and easy to remove all bushings on the Crown jack.

Serial numbers can be found on the A-Frame:

Crown PTH Serial numbers are 3-118400 to 3-999999.

Crown PTH-50 Serial numbers are 7-000000 and higher

Newer Crown PTH-50 Serial numbers 7-500000 and higher

Load Rollers

Load rollers should have neither flat spots nor large pieces of metal imbedded in them (i.e. tacks, nails or metal shavings). Any chips in the wheel that keep it from rolling smoothly indicate the need for replacement.

Always change the wheels in pairs to reduce uneven wear.

New load rollers have an outside diameter of 3" (PTH50) or 3 1/4" (PTH). If the diameter is worn more than 1/4" from normal size, replacement is necessary.

Need to replace your load wheels? See current pricing and availability here.

Steer Wheels

Steer wheels should have neither flat spots nor large pieces of metal imbedded in them (i.e. tacks, nails, or metal shavings). Chips in the wheel which keep it from rolling smoothly indicate replacement.

Steer wheels should turn freely. They should not rub the bottom of the traverse. If they do, check for the correct installation of the snap ring under the traverse.

The PTH50 uses 7” wheels, and the PTH uses 8” wheels. If the diameter is worn more than 1/4" from the normal size, replacement is necessary.

Need to replace your load wheels? See current pricing and availability here.

Handle

Inspect the handle for cracks and structural integrity. There should be minimal side play in the handle bracket. Check for worn bushings.

If bushings are not replaced regularly, the handle bracket holes can become worn. Damaged holes cause pin failure and may require complete replacement. Also, inspect the handle pin and roller for flat areas and wear. If any of the above parts are worn more than 1/16", replace them.

Need to replace the handle? We can show you step by step how to do it in this video:

Hydraulic Unit

Inspection

Inspect the outside of the pump for oil leaks. Test the unit, under a load, to determine if there is a problem. This can be done by lifting a heavy pallet and letting it stand for 15-20 minutes. Below are symptoms and solutions to common hydraulic unit failures. If the following solutions fail to correct the problem, a complete rebuild of the malfunctioning unit may be necessary. Please refer to our website for information about ordering the appropriate seal kit, or take advantage of our hydraulic unit exchange program.

For troubleshooting any of these problems, follow the steps outlined on our website:

- Jack fails to lift load.

- Jack fails to lower

- Jack lifts in short increments

- One fork lifts, the other does not

Service Hints

• Tampering and abuse are two of the most common problems. In most cases, minor repairs become major when inexperienced people attempt to rebuild a hydraulic unit. If you come across a unit that looks like it has been tampered with or modified, inspect the unit carefully to be sure it can be rebuilt or call Generic Parts Service for technical assistance.

• The pump piston and ram are polished to a fine finish for maximum seal life and minimum oil leakage. If you see these surfaces nicked or pitted, this will cause the unit to fail in a short time. Replace any rusty or damaged parts that will cause premature wear on their mating parts or the body of the hydraulic unit.

• Use UNI-HO hydraulic oil. Do not use automotive oil or hydraulic brake fluid.

• If you do need to rebuild your Crown Hydraulic unit, you can learn how-to through our videos:

Part 1: How to disassemble Crown PTH50 Hydraulic Pump from the handle

Part 3: Rebuild the Crown PTH50 Hydraulic Unit with the new seal kit

You can find all Crown replacement parts on our website.

We offer quality after-market parts - OEM quality or better - same day shipping, and technical advise should you need it.

All manufacturers’ names, part numbers and descriptions are used for reference purposes only. We do not imply that any parts are the products of a particular manufacturer. ©Generic Parts Service, Inc. All rights reserved.

Monday, January 18, 2021

Tips for Pallet Jack Safety

They might not be as large and fast as forklifts, but accidents still happen!

The Pallet Jack Pros at Generic Parts compiled some tips (and the list is by no means complete) to keep everyone in the warehouse safe, and to avoid property damage:

Inspect your pallet jack before every use

Always use a jack that is in good shape! Make sure to test the jack thoroughly - rotating the handles, raising and lowering the jack, rolling the wheels, and so on. Replace any parts not working properly immediately to avoid major equipment damage.Wheels and rollers need to be replaced most often since they get the most wear. We have wheels for all the major brands and ship same-day. Our convenient pre-packaged wheel kits contain all parts needed for replacement.

If you not sure how to replace the load rollers or steer wheels, our step-by-step videos will help. You will find other convenient videos on our YouTube channel to help you replace the handle, rebuild the hydraulic unit, and more.

Give sufficient Clearance

Make sure your pallet jack won't unexpectedly catch on anything. Lift the load to give it 1 inch of clearance off the ground. Most of the time that is enough, but check the route in advance to make sure.

Don't let hands or feet get under it

Always be conscious of where you are standing or placing your hands around its forks as you lower the jack. Most of the time raising or lowering the jack is no problem, but don't risk that it will fail and come crashing down with disastrous consequences.

Also be aware of the places where the "pinch" motion could catch your hands or feet. Often hurried work and inattention can lead to avoidable accidents.

Ask for help if you need it

When pushing a jack with a big load that you can't fully see over or around, it's important to not try to move it anyway. Instead, enlist the help of a coworker to ensure you don't run into anything or anyone.

Do not stack materials higher that eye level!

Pull, don't push

Pull the pallet jack whenever possible. Pushing the equipment makes it less maneuverable and you risk running into something, or someone, when going around a corner.

Know your Load

To prevent an unstable load, use a container for smaller items and secure larger items by bundling them up. Make sure the load is evenly distributed. A top-heavy load can tip over. Always load the heaviest items first. Center the forks evenly under the load to maintain good balance and stability and make sure the forks are positioned completely under the pallet. Never overload.

OSHA recommends limiting the weight of loads so the necessary pushing force is less than 50 pounds.

Use Personal Protective Equipment (PPE)

It’s important to have all the vital tools and equipment to make each lifting or handling job both easy and safe. Here are the necessities:

Leather Gloves: Use leather gloves when working with large, heavy materials that have sharp or rough edges.

Back Belts: A back belt is helpful in supporting your lower back while using hand trucks, carts, and pallet jacks. Make sure you have the proper fit and that it is being worn on your lower back.

Protective Footwear: Transporting items in certain areas can put you at risk for foot injuries due to falling, rolling objects or pointed materials that can pierce the sole. You may also need special designs of footwear like non-skid soles and steel-toed boots when there are slip or trip hazards in your worksite.

Additionally

we recommend the pallet truck toe guard, to reduce the risk of the pallet jack rolling over your foot.

Use a pallet jack stop to prevent the jack from rolling out of control especially on an incline.

Remember, Generic Parts Service has quality replacement parts for your pallet jack in stock, and we ship same day if you order before 6 P.M. (EST).

We also carry replacement parts for electric lift trucks and forklifts.

Is pallet jack beyond repair, or you need additional ones? Take a look at our line of quality jacks here.

This information is intended for general information purposes only. This is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion.

IDENTIFY YOUR PALLET JACK!

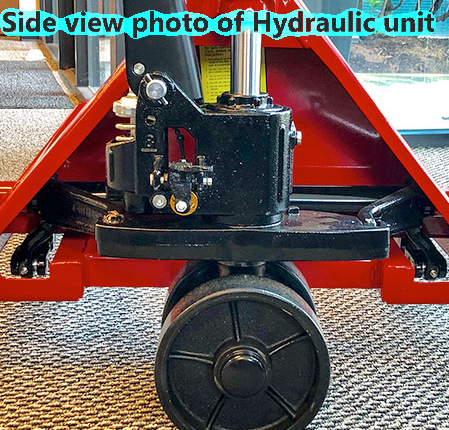

Let us help you identify your pallet jack. 1. Take a side view photo of your pallet jack hydraulic unit. Here is a sample: 2. Email or t...

-

Manual Pallet Jacks are used to lift small stacks of pallets in areas where most of the pallets are stored, at ground level. You ...

-

Looking to install replacement wheels on your Lift-Rite LCM50 manual pallet jack? We have load wheel kits available for this type of equipme...

-

Crown Pallet jacks are still some of the most popular we hear about. Here are some helpful hints when repairing and performing maintenance ...